PayPal now available at checkout

Free US Shipping On Orders $99+

Previous slide

Next slide

The headset is often overlooked and neglected, but it is an essential component to your bike. Your bike’s headset is the bearing assembly that keeps your fork attached to your bicycle, and it’s what allows you to turn your fork and handlebars to steer your bicycle.

All bicycle headsets work in a similar way – there are two bearings, one for the top and one for the bottom of the headtube, and your fork’s steerer tube passes through the headtube with lower and upper bearings.

The steerer tube protrudes out past the upper head tube and is clamped down and held in place by the handlebar stem. Before you clamp the handlebar stem to the steerer tube, the system must be preloaded / compressed together in order for the headset to work and withstand loads and abuse.

The preload force is applied from the handlebar stem and the headset spacers, which should sit slightly taller than the length of the protruding steerer tube – about 3mm or so.

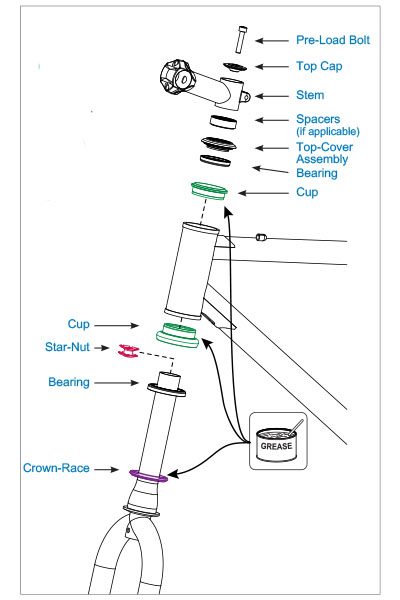

There is a fixed threaded insert, or “Star Nut” inside the fork’s steerer tube that sits a few inches down from the top of the steerer tube. There is a top cap that rests on top of the stem or spacers, and a preload bolt passes through the top cap and threads into the star nut.

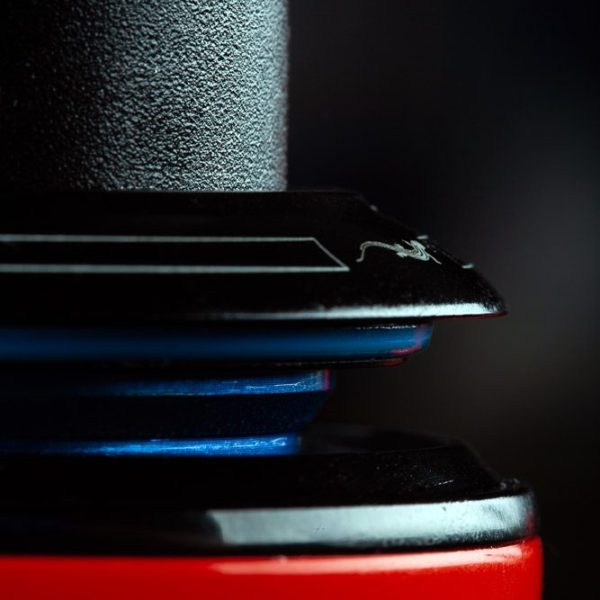

Below the stem or spacers, there is a bearing cover assembly – a cover and seal for the upper bearing, and a split compression ring.

The compression ring interfaces with the upper bearing and steerer tube, which helps keep the steerer tube centered in the headtube.

There is a crown race installed at the base of your fork’s steerer tube – a crown race is an angled surface, or race, that interfaces with the bottom bearing.

As you thread the upper preload bolt down into the Star Nut, the steerer tube will draw upwards, which presses the crown race up against the bottom bearing and pushes the bearing cover/ compression ring down onto the upper bearing, creating the compression that is needed to keep the system snug and secure.

Here is an exploded diagram that may help you visualize the internals of a headset and where the parts go:

There are three things you must determine in order to identify the correct headset you need for your bike:

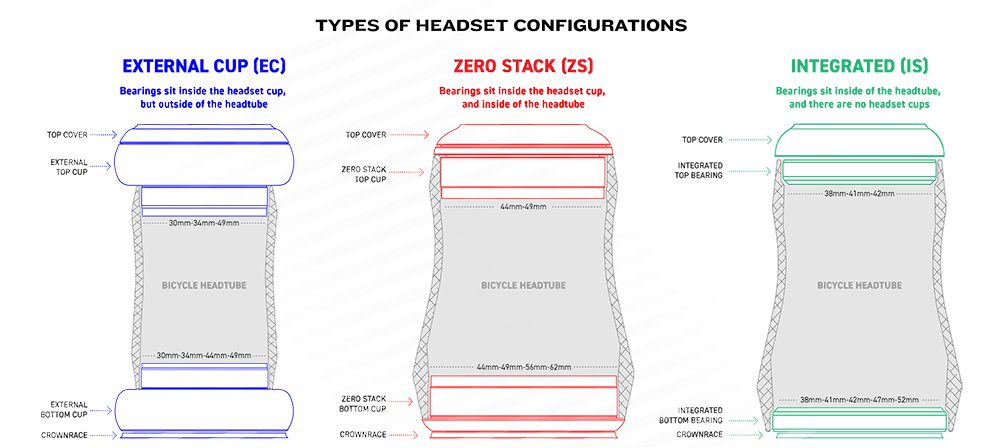

1. HEAD TUBE TYPE – There are two types of head tubes: press-fit, and integrated. Press-fit head tubes require headset cups that are pressed into the bicycle headtube, and the headset bearings sit inside those headset cups.

You can have ZS (Zero Stack) headset cups or EC (External Cup) headset cups. Both of these are for press-fit head tubes, but they are different types of headset cups- the external cup has a much taller stack height because it houses the bearing on the exterior of the headtube, where the Zero Stack headset cups house the bearings inside the headtube.

Integrated (IS) headtubes have molded integrated races inside the headtube that are a part of your bicycle’s frame, and you simply rest the headset bearings onto these integrated races

2. HEAD TUBE DIMENSIONS – A press-fit headtube should be measured with a good set of calipers, the inside diameter in millimeters, of the bare headtube top and bottom.

You’ll likely find numbers like these: 30mm, 34mm, 44mm, 49mm, 56mm, and more recently 62mm.

With an integrated headtube, be sure you are measuring the very edge of the top and bottom bare headtube because the integrated headtube races are angular- if you measure with your calipers in too deep, you could get incorrect measurements.

If you have the stock or original headset bearings, you can measure the outside diameter of those bearings to be sure. You’ll likely find numbers like: 41mm, 41.8mm (we round up and label this 42mm), 47mm, and 52mm.

3. FORK STEERER TUBE DIMENSIONS – Almost every single modern bicycle fork has an upper steerer tube outer diameter of 28.6mm, or also referred to by 1 ⅛ in.

Some forks have straight steerer tubes, and some have tapered. Straight 1 ⅛ in steerer tubes have a crown race seat of 30mm, so they require a 30mm crown race. Tapered steerer tubes can taper out to 1 ¼ in (33mm crown race seat) and sometimes have integrated crown races (like the 2nd image), so no press-fit crown race is needed.

More commonly, tapered steerer tubes will taper out to 1.5 inches, which has a 40mm crown race seat so a 40mm crown race is needed. Most modern single crown mountain bike forks have a 1.5 in tapered steerer tube (40mm crown race)

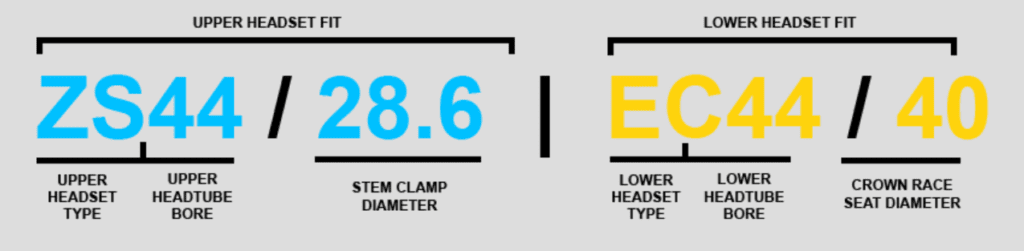

We developed the most commonly used headset identification system – SHIS which stands for Standardized Headset Identification System. We use the measurements you get from the headtube and fork to influence the naming of different headset specifications.

The identifier starts off with two letters which signify the type of headset it is. “EC” stands for External Cup, and “ZS” stands for Zero Stack, “IS” Stands for Integrated System. The numbers following the two letters signify the headtube and fork dimensions.

Take this headset for example: ZS44/28.6 EC44/40. This headset would work for a press-fit headtube with an inside diameter of 44mm top and bottom (ZS44 upper cup and EC44 lower cup) , and the fork has a 1 ⅛ in (28.6mm upper steerer tube) to a 1.5 in tapered steerer (40mm crown race).

A ZS44/28.6 EC44/30 would work for the same 44mm press-fit headtube, but it has a 30mm crown race which would work for a straight 1 ⅛ in steerer tube. A ZS44/28.6 ZS44/30 would also work on the same 44mm press-fit headtube, and also work on a straight 1 ⅛ in steerer tube, but the lower headset assembly would not have as much stack height as the EC44/30 bottom assembly.

ZS44/28.6 EC49/40 will work on a press-fit headtube that has an upper inside diameter of 44mm and a lower headtube inside diameter of 49mm, and a fork that has a 1 ⅛ inch to 1.5 inch tapered steerer tube.

IS42/28.6 IS52/40 would work on an integrated headtube (IS) that has an upper headtube with a 41.8mm inside diameter (which we round up to 42mm) and a lower headtube inside diameter of 52mm, and the fork would have a 1 ⅛ in to a 1.5 in tapered steerer tube. IS41/28.6 IS41/30 would work on an integrated headtube that has an upper and lower headtube I.D. of 41mm and a fork with a straight 1 ⅛ in steerer tube.

The most important thing you can do to keep your headset working properly is to periodically clean the bearings and all bearing surfaces free of all debris / old grease, then reapply a fresh layer of grease.

The first step is to get a surface nearby your workstation to rest your bicycle fork onto when you’ve dropped it from the headtube – You can use a shop stool or set up your repair stand next to the service bench, and in most cases, you should have enough brake housing or brake hose length to reach the stool or bench – this saves you a step later on because you will not need to reinstall the front brake caliper. However, if you feel the need to dismount the front brake caliper to make things a little easier to maneuver, go right ahead.

Loosen the steerer tube clamp bolts

Hold onto the fork with one hand while you loosen the top bolt above the top cap. Loosen this bolt until you feel the bolt disengage with the threaded insert inside the forks steerer tube, you may feel the fork want to fall to the floor.

Pull the fork out from the headtube completely, and set the handlebar spacers, bearing cover assembly, and stem/ handlebar aside. The steerer tube surface and the crown race surface will need to be wiped clean and then you should apply a thin layer of grease to the bearing contact surface of the crown race, and you can set the fork aside.

Pull the upper and lower bearings out of the headtube completely. These bearings need to be wiped clean as much as possible. If you rotate the bearing cartridge between your fingers and the bearings feel too harsh or gritty, or if it looks too corroded to reuse, or if it’s falling apart, then you should replace the bearings – all Cane Creek headsets have replaceable bearings.

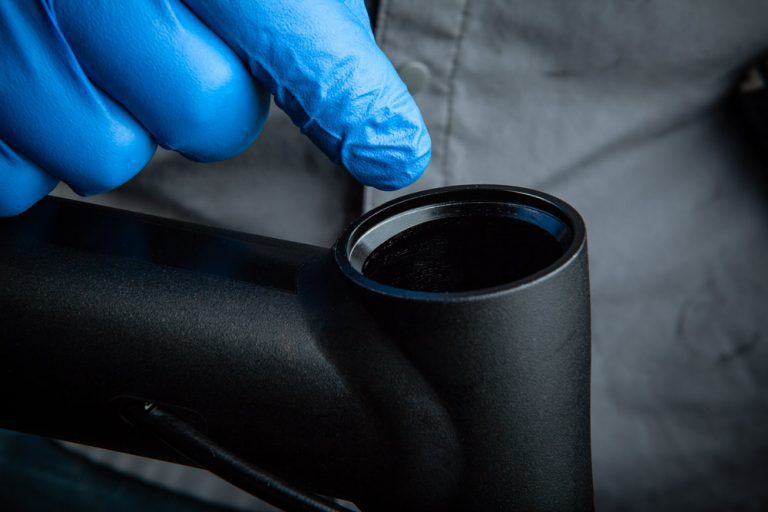

Wipe the headset cups or the integrated races of the headtube completely clean. Then apply a thin layer of grease to those surfaces.

If you determine the bearings are working properly, then apply a thin layer of grease to the bearings and drop the greased bearings back into the headtube.

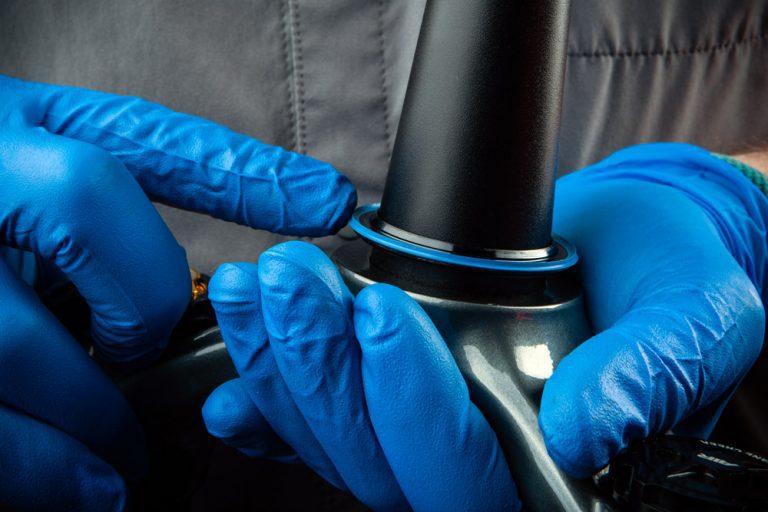

Slide your fork back through the headtube, and hold onto it with one hand. Slide the bearing cover assembly back onto the forks steerer tube and down on top of the upper bearing. Slide your headset spacers and handlebar stem back onto the steerer tube, and put the top cap and bolt back on top of the stem, and begin to preload the headset by tightening the preload bolt.

Align your handlebar stem and apply the appropriate torque rating to the steerer tube clamp bolts.

There is not always an exact torque rating for the preload bolt, so it’s sometimes hard to know if you have applied enough preload, or too much.

If there is too much preload, then your handlebars will not turn easily.

If there is not enough preload, then you will have play between the steerer tube and the headtube – you can check this by setting your bike on the ground, grabbing the front brake, and rocking the bike back and forth. If there is play, you should definitely feel it, and you can also visibly see the play in the gap between the bearing cover and the headtube when you rock the bike back and forth.

A good rule to practice is when you reach down to your handlebar spacers, then you should not be able to turn them easily by hand.

If you can easily turn them, then you likely do not have enough preload. If the spacers are staying in place, and the handlebars are turning like they should, then you’ve applied the appropriate amount of preload.

This article might not cover every single headset scenario in the universe, but it should cover most situations you will encounter with modern bicycles. All Cane Creek headsets are backed by our commitment to customer service. If you have any further questions about one of our headsets, feel free to contact us HERE

Monday: 10:00 am – 5:00 pm

Tuesday – Thursday: 10:00 am – 5:00 pm

Friday: 10:00 am – 5:00 pm

Saturday – Sunday: Closed